Container terminals are bustling hubs where goods from all over the world are loaded, unloaded, stored, and transported using standardized shipping containers. Understanding the different types of containers handled at a terminal is essential for optimizing yard planning, vessel stowage, and logistics operations.

Each container type is specifically designed to suit the nature of the cargo it carries whether it’s dry goods, perishable items, hazardous materials, or oversized machinery. Handling these various container types efficiently ensures safe cargo movement, minimizes port congestion, and supports the global supply chain.

The main container types found at container terminals include:

Dry Containers (General Purpose Containers): The most common type, used for standard dry cargo such as electronics, textiles, and furniture.

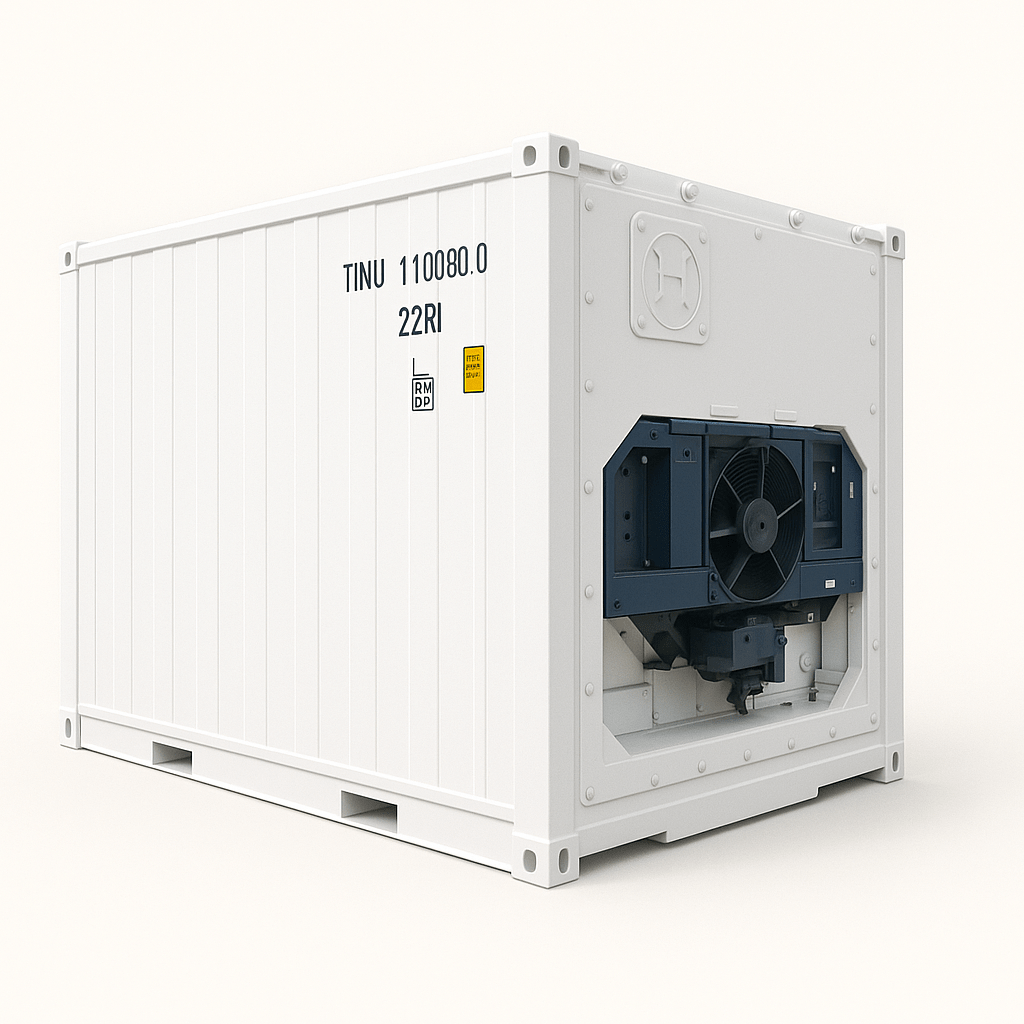

Refrigerated Containers (Reefers): Equipped with cooling systems to transport temperature-sensitive goods like fruits, vegetables, pharmaceuticals, and seafood.

Open-Top Containers: Designed for oversized cargo that can’t fit through container doors, such as heavy machinery and large industrial parts.

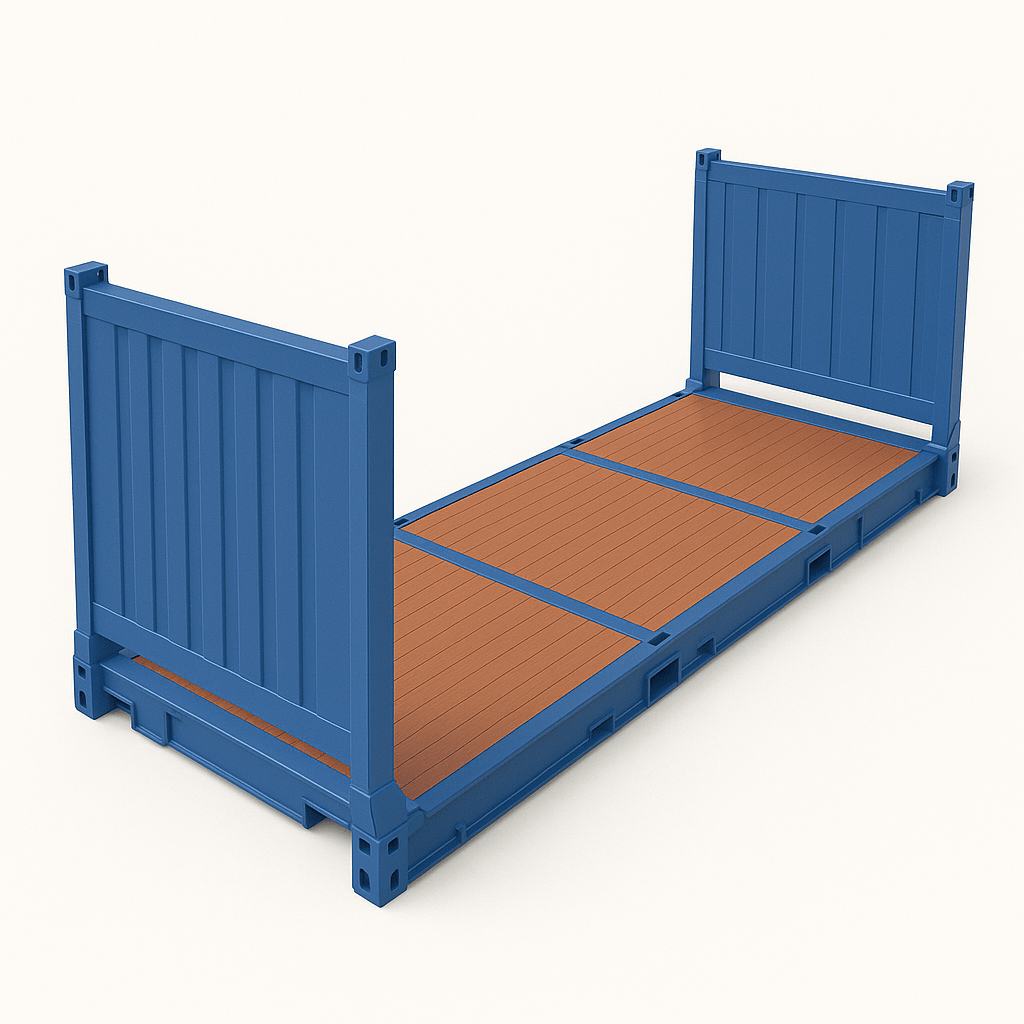

Flat-Rack Containers: Used for extremely heavy or awkwardly shaped cargo that requires loading from the top or sides.

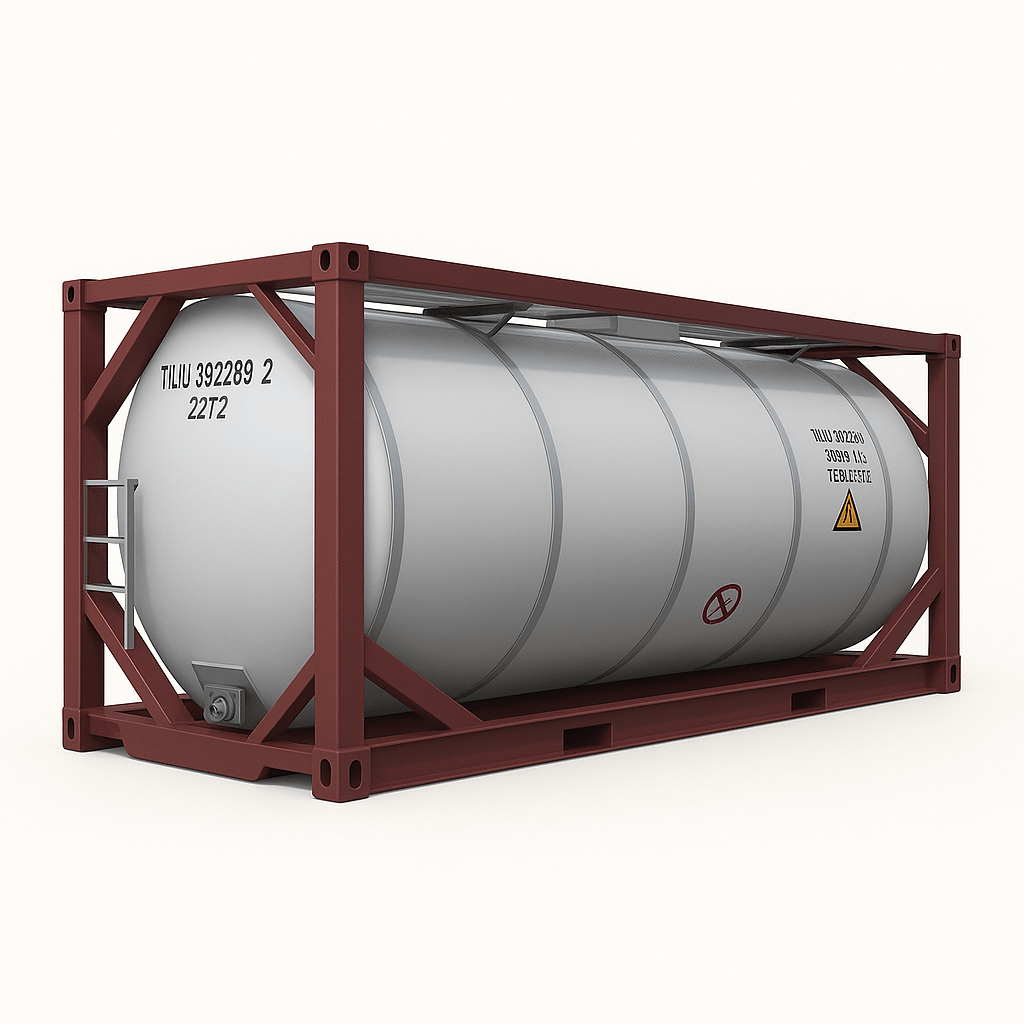

Tank Containers(Tankers): Specialized for transporting liquids, chemicals, and gases in bulk form.

High Cube Containers: Similar to dry containers but taller, offering additional capacity for lightweight, voluminous cargo.

Ventilated Containers: Suitable for agricultural products that require natural ventilation to prevent moisture buildup.

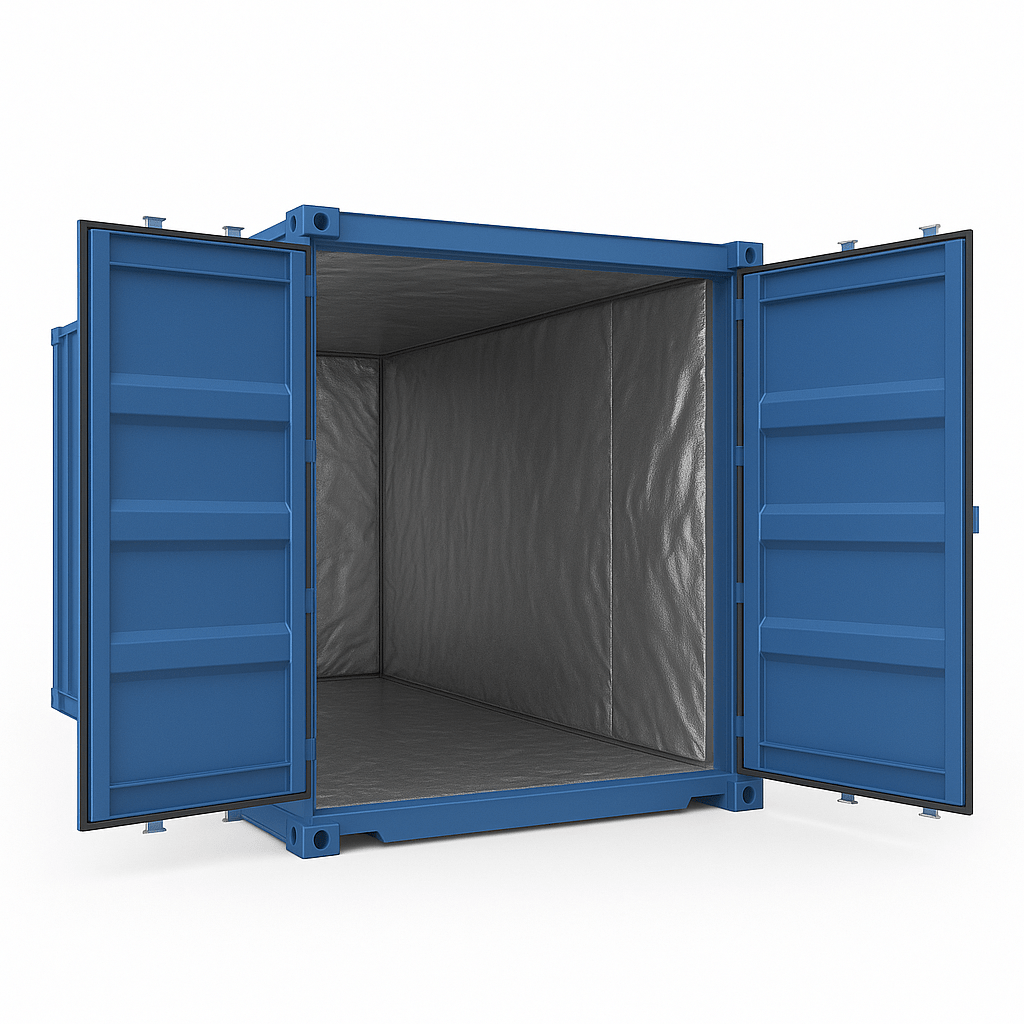

Insulated Containers: Maintain a constant temperature inside without mechanical cooling, ideal for specific cargo needing temperature control without refrigeration.

Half-Height Containers: Used for heavy, dense cargo like minerals and coal, allowing easy loading and unloading.

In a container terminal, each container type demands specific yard arrangements, stacking strategies, and handling equipment. Terminals often have designated zones, plug points for reefers, special storage for hazardous goods, and strong flat areas for heavy cargo.

Understanding container types is not just important for operational efficiency but also critical for maintaining cargo safety, adhering to international shipping regulations, and maximizing terminal throughput.

Leave a comment